RGL Associates is actively involved in the following research activities in support of its expertise in rolling bearing technology

- Fracture mechanics interpretation of rolling bearing fatigue

- Developments in current bearing steel cleanliness assessment techniques such as ISO 4967, ASTM E45 and ASTM E2283, principally by the use of the generalised Pareto dstribution (GPD)

- Fatigue tolerant assessment of bearings by means of FE analysis of rolling contact stresses and steel cleanliness modelling by GPD

- Analysis of tessellation stresses around inclusion to assess their effect upon micro-crack initiation and growth

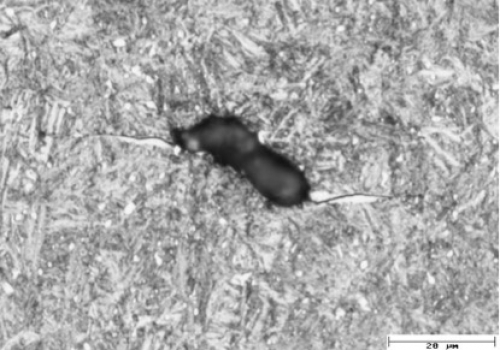

- Study of the mechanism of formation of butterfly wings

- Study of micro-crack initiation at inclusions

- Study of micro-crack growth rates from inclusions and the potential for crack arrest that may lead to infinite life

- Study of the validity of the Miner-Palmgren fatigue damage accumulation rule for dynamic stresses encountered in wind turbine bearings

- Developments to ISO 281, the current standard for bearing life assessment, to recognize varying cleanliness levels in bearing steels

- Developments to ISO 281 to improve life assessment for slowly oscillating bearings used for pitch and yaw systems in wind turbines